Lemgruber® elastic tubing has been used as an adjunct to exercise training with positive effects in healthy adults and in patients with chronic lung disease. Despite its benefits, there is a lack of information on the specific resistance, elongation, reproducibility and safety of the different types of Lemgruber® elastic tubing.

ObjectivesThe primary outcome was to assess the length-resistance relation (E/R) of five Lemgruber® elastic tubing of different diameters. Secondary outcomes included the development of reference equations of resistance according to elongation of Lemgruber® elastic tubing types and; the description of Lemgruber® elastic tubing safety and; the description of elongation of Lemgruber® elastic tubing using a clinically useful outcome (i.e. range of motion, in degrees).

MethodsThe relation between elongation and resistance of Lemgruber® elastic tubing was investigated in a laboratory environment. Secondly, reference equations for the resistance according to the elongation in each Lemgruber® elastic tubing were calculated. Finally, the elongation of the tubing during movements in different degrees of range of motion were estimated using mathematical models, so that the resistance provided by the tubing for any exercise could be predicted.

ResultsLemgruber® elastic tubing provided a large array of resistance varying from 3±0.1Newtons (N) to 537±13N (mean±standard deviation). The maximal resistance deemed safe for each of the five Lemgruber® elastic tubing were: 173±25N, 280±23N, 409±40N, 395±37N and 537±13N. Reference equations had nearly perfect predictive power (r2=0.99) for all polynomial non-linear models (p<0.001 for all).

ConclusionsLemgruber elastic tubing progressively increased resistance with increased elongation. The large array of resistances delivered by Lemgruber® elastic tubing, along with its safety and good estimation of reference values, support its use in clinical practice.

Elastic resistive devices such as bands and tubing are tools that are frequently used in exercise programs. The low cost and portability compared to conventional weight machines allow it to be easily used at home as well as in environments with limited space.1–5 The American College of Sports Medicine recommends exercise training using elastic resistance as a valid therapeutic option.6–8 Unlike the constant resistance occurring during conventional resistance exercise (i.e. using dumbbells/barbells or weight machines), resistance when using elastic bands or tubing varies according to the elongation of the elastic material.9 Consequently, highest resistance during concentric exercise is delivered at the point where muscles are at their shortest length (i.e. end of the elongation of the LET).10,11 Interestingly, positive effects of elastic resistance are observed and comparable to conventional resistance training.12–16 Additionally, elastic bands can be used as an adjunct during exercise. For example, it has been shown that the bands improve joint balance during walking exercise (i.e. by reducing rearfoot eversion).17

Lemgruber® elastic tubing (LET) is an affordable type of elastic tubing that has been used in exercise training programs with positive effects on peripheral joint muscle force and functional exercise capacity in healthy adults18 as well as in patients with chronic lung diseases.1,19,20 Despite their potential benefits, there is only limited information regarding the mechanical properties of LET, such as details about the reproducibility of repeated elongations, or the maximal elongation considered safe. This information is typically provided by the manufacturer; however, it is common that only limited details are described.21 In addition, in clinical practice, it is difficult to estimate the force generated by the elastic material during movements in different ranges of motion (ROM) hampering therapists from being confident about the magnitude of resistance offered through the ROM (i.e. elongation of the tubing)during training. An increased knowledge of the above mentioned problems would certainly help therapists to be more confident in elaborating and prescribing exercise training protocols. Details about the mechanical properties also help to guarantee safety during exercise as improper use of different elastic materials has been reported to be harmful.9 Therefore, the aims of this study were: (1) to assess the length-resistance relation of elongation and resistance of five LET of different diameters; (2) to describe the safe use of LET; (3) to establish reference equations of resistance according to elongation of the five LET and; (4) to describe elongation of LET during movements at different degrees of ROM.

MethodsStudy designIn this descriptive laboratory study,22 the main goal was to investigate the clinical applicability of LET. This was done by analysing the mechanical properties, safety and the resistance delivered during elongation of tubes adopting the following strategy: Firstly, LET of five different diameters had the relation between their elongation and resistance investigated using a laboratory experiment. Secondly, reference equations for the resistance according to the elongation in each LET were calculated. Finally, the elongation of the tubing during movements in different degrees of ROM were estimated using mathematical models, so that the resistance provided by the tubing for any exercise could be predicted.

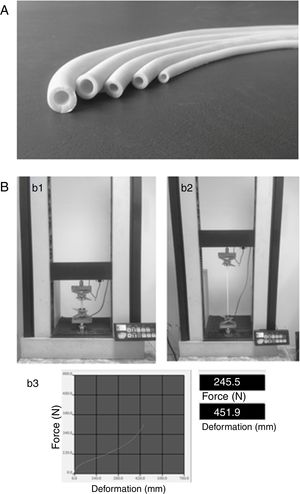

Length-resistance relation of elongation and resistanceFive LET sizes were used (Fig. 1A). Internal (ID) and external diameter (ED) of each tube are described according to manufacturer specification: LET#200 (ID: 3.0 millimetres (mm), ED: 5.5mm); LET#201 (ID: 4.0mm, ED: 5.5mm), LET#202 (ID: 4.0mm, ED: 8.0mm), LET#203 (ID: 6.0mm, ED: 9.0mm) and LET#204 (ID: 6.0mm, ED: 11.5mm).

(A) Lemgruber® elastic tubing; from the left to the right: LET#204; LET#203; LET#202; LET#201 and LET#200. (B) Visual representation of the mechanical testing. Tubes are clamped on the machine by two pressure claws (b1) and subsequently stretched at the rate of 500mm/min (b2). The equipment was composed of a load cell, which in turn collected the force values applied by the equipment every deformed millimetre. This force was sent to a specific software (Maqtest), which reported, in real time, the length of the deformation (in millimetres – mm) and the force that the equipment performed for such deformation. The software also performed in real time a plotting of force versus deformation (b3), presenting the characteristic curve of the material under analysis.

The different sizes (mm) of tubing were submitted to experimentation using a mechanical testing machine following the standard testing method for vulcanized rubber and thermoplastic elastomers tension (ASTM D412-06a).23 In summary, the tubing were fastened to the testing machine (EMIC model DL 2000) and elongated at a constant speed of 500mm/min until maximum capacity (i.e. the point where tubing were damaged or the point where the values of resistance stopped increasing despite further elongation) was reached.5 The procedure was repeated five times with each LET size (with each repetition using a different tube sample of the same size) and the average of measurements was used as the resistance for each point of elongation. Reference equations were calculated using linear and non-linear curve-fit models for each of the five LET sizes. A visual description of the mechanical testing is provided in Fig. 1B.

Maximum elongation deemed safe (MES) was defined as the length 10% lower than the maximum length of the samples achieved during the mechanical testing (e.g. if a tube would rupture or present damage in the mechanical testing at 50cm, the MES would be 45cm). In clinical practice, the knowledge of the MES would allow the therapist to easily calculate maximal length of the tube deemed safe in different initial lengths. Mathematically, maximal safe length to be used during exercising is calculated using the following equation (Eq. (1)):

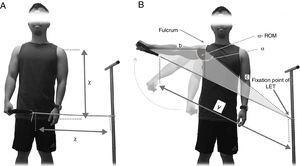

Elongation during different ROMThe resistance delivered by LET during resistive dynamic exercises can be derived from the extent to which tubing elongates for the various ranges of motion (expressed in degrees). To this end, the elongation of tubing at different ranges of motion was calculated based on the general law of cosines using the following equation (Eq. (2)):

where ‘γ’ is the length of the elongated tube, ‘b’ is the length of the lever of the movement, ‘c’ is the length between the fulcrum and the fixation point of LET and ‘α’ is the angle between ‘b’ and ‘c’. An illustrative example of this calculation during a shoulder abduction movement is described in Fig. 2. On the left-hand side of the figure (i.e. before the movement), the lengths of both the tube and the lever of movement (i.e. subject's right arm) are equal. In the right-hand side of the figure (i.e. during the movement), the tube elongates as the shoulder abducts (the length of the lever, however, remains the same). During the movement, α increases and, consequently, the length of tube increases. The percentage of elongation is given using the following equation (Eq. (3)):where ‘γ’ is the length of the elongated tube and ‘χ’ is the initial tube length. A reference equation to estimate elongation according to the range of motion was calculated using an ideal lever of 1m and LET without pre-elongation of the same length at angles varying from 0° to 270°. The resulting equation is provided in the results section.Example of the calculation of elongation during a shoulder abduction movement. (A) Initial tube length (without pre-elongation) and lever of movement were equal in size (χ); (B) after the complete desired movement (α=90° shoulder abduction) the total length of the tube was calculated as: length=χ+tube elongation.

The trigonometry functions used to estimate elongations of LET according to the different ROM (i.e. general law of cosines) were calculated using Excel (Microsoft Corporation, USA) for every angle between 0° and 270°. Data analysis was conducted using the software Prism (Graphpad, USA). Shapiro–Wilk tests were used to test the normality of the data. Comparison of maximal resistance and elongation between tubes was performed using One-Way ANOVA with post hoc of Dunns. The equations to (1) estimate resistance according to elongation and to (2) estimate elongation according to ROM were performed using linear and non-linear regression models. The comparison of the slopes generated in ‘1’ was calculated using the Zar's method (F test). Linearity of slopes was calculated using piecewise regression in MatLab (MathWorks, USA) and values of the first and second inflection points of the curves were deemed the points where change in linearity occurred. A p value lower than 0.05 was considered to be statistically significant.

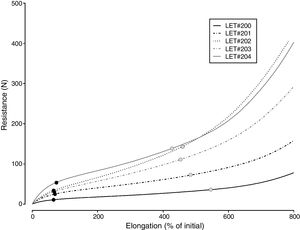

ResultsMechanical testing measurementsFig. 3 shows the results of the elongation in the five different sizes of LET. Values reported were limited to 800% of initial length. All tubing presented similar and non-linear behaviour in the length-resistance slopes. The slopes demonstrated steeper increase in resistance at the beginning (68±3% of initial length) of the elongation (1st inflection point of slopes) followed by a steady increase until 475±44% of initial length, when it becomes steeper again (2nd inflection point of slopes). The length-resistance comparisons demonstrated differences between all five slopes (p<0.0001, F=79,461).

Length-resistance slopes of the five LET#200–#204 Lemgruber® elastic tubing. Black dots represent the 1st inflection point. Grey dots represent the 2nd inflection point. The areas between the black and grey dots are linear zones; areas outside the dots (left of black dots and right of grey dots) are the non-linear zones. p<0.0001 for comparison between all slopes (Zar's method).

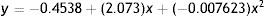

Since the slopes were statistically different, reference equations were generated for each tubing size instead of one general equation for all. Two regression models were adopted (i.e. linear and polynomial non-linear) with equations and respective statistical significance and r2 values reported in Table 1. All equations reached r2 between 0.88 and 0.94 for the linear models and r2 of 0.99 for the polynomial non-linear models (p<0.001 for all).

Reference equations for the resistance according to elongation.

| Tubing | Linear model | r2 | p | Polynomial non-linear model | r2 | p |

|---|---|---|---|---|---|---|

| #200 | y=(0.1159)X−2.745 | 0.88 | <0.0001 | y=(3.795×10−7)X3+(−0.0003623)X2+(0.14388)X+1.896 | 0.99 | <0.0001 |

| #201 | y=(0.2042)X+1.144 | 0.91 | <0.0001 | y=(6.443×10−7)X3+(−0.0006386)X2+(0.2913)X+4.994 | 0.99 | <0.0001 |

| #202 | y=(0.4097)X−3.978 | 0.94 | <0.0001 | y=(1.287×10−6)X3+(−0.0009377)X2+(0.4568)X+4.811 | 0.99 | <0.0001 |

| #203 | y=(0.3435)X−3.927 | 0.94 | <0.0001 | y=(8.810×10−7)X3+(−0.0007368)X2+(0.3824)X+5.306 | 0.99 | <0.0001 |

| #204 | y=(0.4501)X+0.6974 | 0.91 | <0.0001 | y=(1.485×10−6)X3+(−0.001311)X2+(0.5828)X+11.30 | 0.99 | <0.0001 |

y=resistance expressed in Newton; X=elongation expressed in percentage of initial.

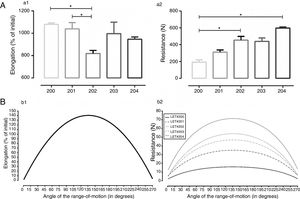

Maximum elongation and resistance of all of the LET are described in Fig. 4A. All tubes presented similar maximum distension except for tube LET#202 which had significantly smaller values than LET#200 and LET#201. There was an expected increase in maximum resistance from tubes LET#200 to LET#204. Maximal resistance was significantly different between LET#200 and LET#202 and between LET#200 and LET#204 (p<0.001 for both). Maximum values of resistance deemed safe of each tubing were 173±25N (LET#200), 280±23N (LET#201), 409±40N (LET#202), 395±37N (LET#203) and 537±13N (LET#204).

(A) Maximum elongation and resistance of LET. (a1) Maximum elongation expressed as a percentage of the initial length and; (a2) maximum resistance at the point of maximum elongation. (B) Relation between elongation of tubes and the degrees of the range-of-motion; (b1) plot describes changes in the elongation of the tubes as per the angle of the range-of-motion; (b2) plot describes the resistance generated by each LET as per the angle of the range-of-motion. N=Newton; #200–#204=Lemgruber® elastic tubing. *p<0.001.

The values of elongation according to ROM varied non-linearly. Assuming the length of the lever (i.e. the motion lever) and the tubing to be equal, the maximal elongation was obtained during 136 degrees of ROM with subsequent reduction of elongation despite increase in the ROM. Considering the anticipated non-linear behaviour of the slope, the polynomial non-linear regression model was used (r2=0.99, p<0.0001) and the resulting reference equation for the calculation of elongation according to ROM, of which “y” was the tubing elongation (in percent) and “x” was the ROM (in degrees) (Eq. (4)). Fig. 4B depicts the slopes of elongation and the resistance created by each piece of tubing along the different degree points of the ROM.

DiscussionThe present study has detailed the resistance values delivered by the Lemgruber® elastic tubing for elongations as large as 800% of initial length. Further, it created reference equations with nearly perfect precision to identify resistance according to elongation and identified maximal elongation considered safe for all the investigated tubing lengths. Last, it described the resistance of the tubing during movements in different degrees of ROM, so that the resistance of LET during any particular exercise could be predicted.

The mechanical analysis of LET confirmed a progressive increase in resistance during elongation. This is not particularly surprising and has been observed in other studies investigating different elastic materials.21,24 The investigation of LET revealed an unexpected large array of resistance varying from 3±0.1N (10% of elongation in LET#200) up to 537±13N (880% of elongation in LET#204). This is of clinical relevance as therapists would require a large number of devices to deliver a similar resistance array using conventional resistance training such as dumbbells/barbells or multi-gym machines. Amongst the five investigated LET, LET#202 delivered the widest variation in resistance from 8.1±0.7N at 10% elongation to 405±38N at 785% elongation. Of note, LET#202 generated more resistance than #203. Although it seems intuitive that an increase in the size of the tubing should be followed with increased tubing resistance, the difference in the diameters of tubes explained the decay of the resistance. LET#202 have a larger internal diameter than #203 with similar external diameter (cfr. methods section). In practice, this meant that there was more elastic material being strained in #202 than in #203.

The investigation of elastic properties of elastic materials is not new. In fact, there have been studies with varied designs reporting similar behaviour of elastic materials as those observed in the present study.3,5,21,24,25 Linearity of LET resistance was similar irrespective of diameter. There was a linear behaviour between 68% and 475% of elongation, which was in line with previous evidence investigating elastic material for muscle training.9 It is important to state that the non-linear behaviour of the tubing outside the interval just described conferred the polynomial non-linear regression models nearly perfect predictive power (r2=0.99) and better than linear models (r2=088–0.94). Simoneau et al.5 evaluated the resistance of tubes and elastic bands (i.e. yellow, green and black – The Hygenic Corporation). Values for 100% elongation of the three colours ranged from 14.4N (yellow) to 39.1N (black) in the elastic bands and 4.2N (yellow) to 34.2N (black) in the elastic tubes. In perspective, the LET used in the present study ranged from 13N (#200) to 58N (#204) for the same 100% elongation. Regarding the safety of tubes, LET could be safely elongated to a wider percentage (i.e. 800%) of initial length (safer compared to those recommended for Theraband® bands/tubes, i.e. not more than three times the initial length of the material).21

We observed a smaller elongation capacity of LET#202 compared to all other LETs. This was statistically smaller in comparison with #200 and #201. In practice, this does not seem to be specifically an issue as elongation values were as high as 8 times the initial length in LET#202. Further, this smaller elongation did not imply that less resistance was being generated as observed in Fig. 4A (a2). Lastly, in clinical practice, resistive dynamic exercises to upper and lower limbs are delivered within a pre-established ROM. In the present study, the elongation and their respective resistances for all of the five LET were thoroughly described. The information will help therapists deliver exercise with previous knowledge about the resistive load until a point considered unsafe. Importantly, the presented reference values were solely based on tubing without pre-elongation. This is not particularly an issue as resistance could be increased with additional parallel tubing or even using pre-elongation of tubing. When only tubes of the same diameter are available, the therapist could add pre-elongating tubes to increase resistance for a large array of exercises. In this specific case, we recommend using LET#200 as it delivered the widest variation in resistance and, therefore, could be seen as more versatile in such a scenario. For the convenience of the reader, the authors have provided an online supplement sheet with the calculation of estimated resistance of all tubing during eighteen different movements. The calculation provided account for differences between individual lever lengths (online supplement 1).

The results of the present study may affected by some potential limitations. The mechanical experimentation of the tubing was done using only pieces of the same length (50mm). A previous study, however, reported that different lengths deliver the same resistance when equal elongations (in percent) were compared.9 The properties described in the present study were conducted under an ideal controlled situation. Real life situations will certainly have an impact on the durability of the LET and consequently, impact on the resistance available and the safety of the material. Although it is hard to estimate the durability of the LET, unpublished data from our research group has not demonstrated fragility of the material when used in a daily routine. Furthermore, safety is unlikely to be severely compromised, as LET were safely elongated to values as high as 800%, which are much larger than the ROM of common resistive dynamic exercises (Fig. 4). In conclusion, Lemgruber elastic tubing (LET) progressively increased resistance with increased elongation. The large array of resistances delivered by LET associated with its safety and good reference values estimation, support its use in clinical practice.

Conflicts of interestThe authors declare no conflicts of interest

This study was supported by São Paulo Research Foundation (FAPESP) [Grant number2014/08011-4]. CAC is funded by CAPES Foundation/Brazil. The authors would like to thank the physical therapists Guilherme Tacao and Felipe Machado for the photos in the present study. We also thank Prof. Vinicius Cavalheri, Ph.D., for reviewing the manuscript.